Hammer Bits

Givens International Drilling Supplies offers DTH hammer bits in all shanks and sizes. We have many sources for bits, which enables us to find the bits you need when you need them. We are a proud distributor of bits made by the DTH hammer companies we represent. Contact us today for all your hammer bit needs!

Face Design

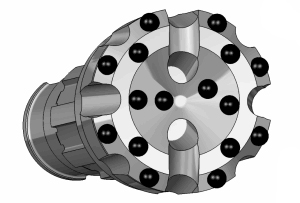

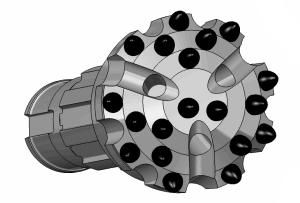

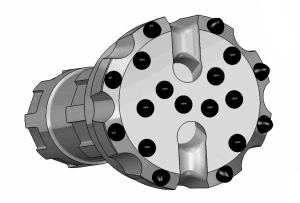

Hammer bits are offered in three basic face designs: concave, convex, and flat face. Each are designed for specific applications and conditions and for varying rock types and hardness.

|

Concave is an excellent all around face design and is used as a general-purpose bit for most conditions while drilling a very straight hole. |

|

Convex bits are used for a combination of speed and service life. Having 2 gage rows, they are also suited for hard, abrasive rock. |

|

Flat face bits are best suited for broken or fragmented ground and hard formations. |

Not sure which face design is best for your application? Contact us, and we will be happy to assist you!

Tungsten Carbide Insert Design

Hammer bits come equipped with tungsten carbide inserts (buttons), which are offered in three basic designs: dome, ballistic, and parabolic. You may also request conical or double dome buttons, or a combination of buttons with one type on the face of the bit and another type on the gauge of the bit. In addition to button shape options, many hammer bit manufacturers offer carbide grade options such as Dynite, DP65, and Diamond Enhanced. Call Givens to explore your options.

|

Dome is the most common button design and is used in all applications. Its tough shape makes it durable and best suited for hard abrasive rock and deep hole drilling. |

|

Ballistic buttons are best suited for less abrasive sedimentary deposits where speed is vital. They are commonly used in convex face bits and are less suited to badly broken ground and hard rock. |

|

Parabolic buttons combine the durability of the dome design and the increased speed of the ballistic design and are less suited to broken ground. |

Have questions about button designs or carbide grades? Contact us for help determining which is best for your application.

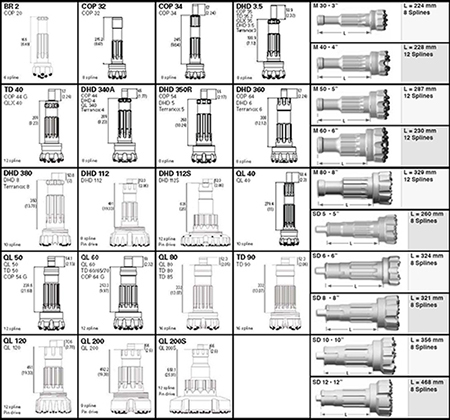

Shank Identification

Not sure what shank your hammer has? Take a look at our bit shank identification chart to view some of the most common shanks. If you don’t see the bit you need on the chart, contact us for help identifying your shank.

The MC line of bits are made by Mincon.

| The MC30 bit | The MC41 bit | The MC51 bit | The MC61 bit | The MC81 bit | |

|---|---|---|---|---|---|

|

|

|

|

|

|

| Splines | 8 spline | 10 spline | 12 spline | 12 spline | 16 spline |

| Length of shank | 5 .120" | 5.827" | 7.007" | 7.441" | 8.74" |

The M30, M40, M50, M60 and M80 shanks shown in the chart below are Sandvik (Mission) bits.

|

View larger image |

Givens also carries Bulroc Hyper and BR bits, Numa N bits, and Halco Mach bits.